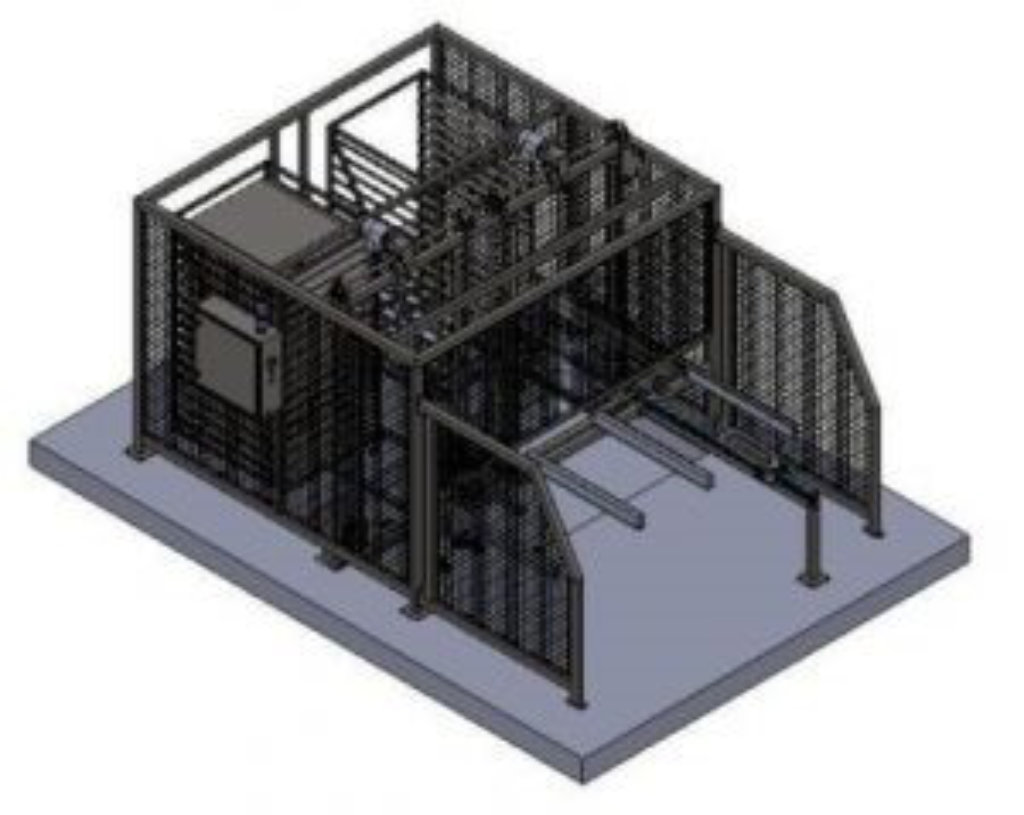

Lift System

Our lift system is specially designed to automatically remove empty baking sheets from the oven rack and replace them with full ones. This entire process occurs fully automatically and does not require three-phase power. A regular 220V power supply can be used in combination with an air connection.

The baking sheet lift is entirely made of stainless steel, making it easy to maintain. The machine operates quietly and efficiently.

Drive

The drive for both lift systems is achieved through a plug-in motor controlled by frequency. The loading and unloading of baking sheets occur through rodless pneumatic cylinders. The lift system can operate entirely independently and only requires a signal indicating the need for an empty baking sheet.

Baking Sheet Detection

Baking sheet detection is performed using sensors. The lift system is designed in a way that whether the oven rack is full or not doesn’t matter. The first sensor detects the position where a baking sheet can be located, while a second sensor determines if a baking sheet is present or not. Therefore, it doesn’t matter if the oven rack is full, or even if additional baking sheets are added or removed during the process.

The drive for both lift systems is achieved through a plug-in motor controlled by frequency. The loading and unloading of baking sheets occur through rodless pneumatic cylinders. The lift system can operate entirely independently and only requires a signal indicating the need for an empty baking sheet.

Baking Sheet Detection

Baking sheet detection is performed using sensors. The lift system is designed in a way that whether the oven rack is full or not doesn’t matter. The first sensor detects the position where a baking sheet can be located, while a second sensor determines if a baking sheet is present or not. Therefore, it doesn’t matter if the oven rack is full, or even if additional baking sheets are added or removed during the process.